|

| February 07, 2017 | Volume 13 Issue 05 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Lightweighting expertise demonstrated with ultralight door module

Magna International, in cooperation with the U.S. Department of Energy (DOE) and partners FCA US and Grupo Antolin, recently announced that it has developed a new, ultralight door architecture that achieves a project objective of 42.5 percent mass savings compared to an average current production door. Magna made the announcement at the 2017 North American International Auto Show, where the company's project partners presented the solution to further help global automakers meet emissions standards and reduce fuel consumption through lightweighting.

The Magna team reimagined a door architecture from scratch.

Magna's advanced engineering team -- a collaborative effort between the company's corporate R&D and various product groups -- combined its unique, full-vehicle perspective on the design of a driver's-side door with an inventive mix of materials and technology to tackle the challenge of significant weight reduction. This product demo was developed in less than 10 months while keeping the cost within accepted industry parameters and providing a solution that applies to approximately 70 percent of the light vehicle market.

How'd they do it? "The team started from scratch and reimagined the way we think about the design, development, and material use of a door architecture," said Swamy Kotagiri, chief technology officer, Magna International.

Magna built on its know-how from the development of the Multi-Material Lightweight Vehicle (MMLV) with the DOE and Ford in 2014, and took it a step further in creating a solution for the advanced ultralight door project.

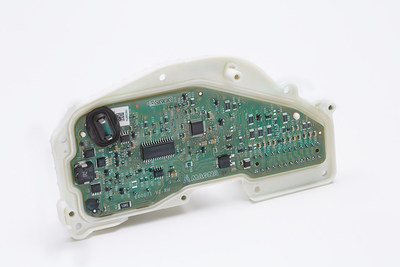

A key innovation associated with the development of the ultralight door includes integration of Magna's SmartLatch electronic latch system, which was selected as a 2016 Automotive News PACE Award winner. This design for side-door latches operates 100 percent electronically, with no cables, rods, or moving handles in the door. This eliminates the need for mechanical hardware and enables the development of a unique carrier module with integrated glass guides and lift capability of a lightweight hybrid glass laminate, an industry first.

Magna's SmartLatch technology represents a new standard for automotive door latches by operating 100 percent electronically.

SmartLatch was first used on the BMW i8, with the system launching soon on another new luxury sedan. Other benefits touted include a reduced number of components; the flexibility to be used in any type of car or truck; and improved safety, sound quality, and vehicle styling.

The door-in-white assembly makes extensive use of aluminum, which achieves approximately half of the total mass reduction of the door assembly. Overall, the project makes use of materials readily available today that can easily be made using existing manufacturing processes, without a significant increase in production costs or changes in body-shop infrastructure.

Grupo Antolin contributed its know-how in the design and manufacture of interior trim components to contribute to the significant mass reduction. The application of advanced molding technologies and polymers contributed approximately 7 percent to the total mass reduction.

VIDEO: See how Magna's SmartLatch works.

The ultralight door development included intensive simulation efforts, passing all safety and durability testing in the process. The next steps include manufacturing full-scale prototype door assemblies, performance tests, and safety tests to validate the design, with the goal of being available for use in production vehicles by the fall of 2020.

The FCA US engineering team has been an integral part of the design and development of the ultralight door, providing engineering collaboration to confirm compatibility with existing assembly operations as well as CAE durability, fatigue, and safety analysis. FCA US plans to conduct testing of prototype door assemblies and full vehicles to validate the results of the predictive simulation.

This project is based upon work supported by the Department of Energy, Office of Energy Efficiency and Renewable Energy (EERE), under award number DE-0007306.

Source: Magna International

Published February 2017

Rate this article

View our terms of use and privacy policy